|

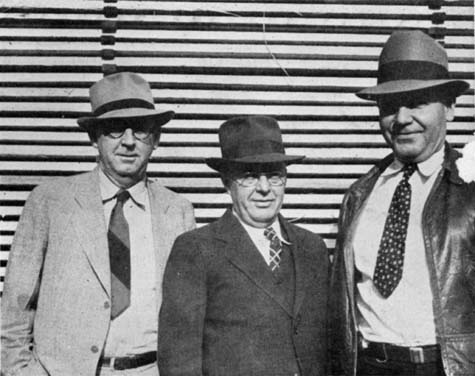

| With Wier at Wiergate (Gulf Coast Lumberman, 1937) |

|

| |

|

|

| |

Source: "With Wier at Wiergate", Gulf Coast Lumberman, November 15, 1937. Bound in a scrapbook in the collection of Lester Haines. |

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| Logs from the "last great stand" of virgin Long Leaf West of the Sabine. This pond has never been empty in Wier's 19 years of operation. |

|

|

|

|

|

|

| |

|

|

| |

For nineteen years the Wier Long Leaf Lumber Company has been operating a mighty sawmill plant at Wiergate, Texas, near the Sabine River, grinding away into the "last great stand" of virgin Long Leaf Yellow Pine timber remaining west of the Sabine.

When Wier built that great mill, equipped and a circular ( the biggest sawmill under one roof west of the Mississippi in the South) they likewise put in a grand logging equipment and with three head-rigs -- two double-cutting bands setup to supply the big mill with logs. So successfully has the woods crew operated that for nineteen years the mill has never once caught up with the woods. It came mighty near to it one time, but never quite made it. Nineteen years for a big mill to never run out of logs for a single hour, is some record.

Likewise, when they built that big mill, they also installed the latest and best equipment that money could buy for seasoning and drying their lumber and preparing it for market. They built twelve big brick dry kilns equipped by the Moore Dry Kiln Company with their then latest devices for quickly and properly seasoning Long Leaf Pine, and that department has likewise given good service, although sometimes it kept the kilns on the double jump to keep pace with the flood of lumber those three head-rigs poured out of that mill. So six months ago Wier decided to bring their nineteen-year-old mill up to the minute in lumber seasoning; for in nineteen years wonders have been accomplished through experience and experimentation in drying Long Leaf Pine by kiln.

Kilns Modernized by Moore

Wier made a deal with the Moore Dry Kiln Company to modernize their kilns, and while they were about it they went the limit and did the biggest and best job that Moore knew how to furnish. They turned a number of their kilns into the modern cross-circulation fan type. They installed a beautiful and efficient control room for the scientific handling of these kilns, and they are at the present time going ahead and modernizing more of their kilns in the same fashion.

They find that a dry kiln equipped with the cross-circulation fan system allows them to stack their lumber tight edge-to-edge on the kiln cars, as shown in accompanying pictures, thus increasing the capacity of the car and kiln about 60 per cent; the lumber dries in less time than in the old type kiln; it dries more uniformly; it leaves considerably less degraded lumber. Thus Wier finds that under this new drying system they increase their production of each modernized kiln at least 60 per cent, and likewise improve the quality of their kiln dried product. And, since they put everything except their timbers, and their number three lumber through the kilns at Wiergate, this improvement is something they are very enthusiastic about. Mr. E. J. Booth, manager at Wiergate, and Mr. Emmett C. Lee, his assistant, are both unstinted in their praise of the change that has been brought about in their lumber seasoning by the new kilns.

This is in line with the Wier idea of keeping their mill always up to the highest pitch of efficiency. When the visitor approaches the front of the sawmill at Wiergate, his first impression is wonderment at the great size and length of the logs with which the pond is invariably filled.

For the Wier timber is amazingly big timber. Not long ago they were building a new water tower at the plant.

They needed a great stick of timber to act as a derrick pole in the erection of that high tower. They went into the woods and came back with a Pine log that should be historical. It was 117 feet long, 1 O Y2 inches at the top, yet so slight was the taper that the butt was just 28 inches in diameter. They erected this great boom and used it to build the tower. It was sound as a dollar, and was cut up into logs and then into lumber, when this service was complete. But this gives an idea of the sort of timber they have at Wiergate, and its possibilities. |

|

| |

|

|

| |

|

|

| Reading from left to right, are E. J. Booth, mill manager; T. P. Wier, vice-president and treasurer; E. C. Lee, assistant mill manager. |

|

|

|

|

|

|

| |

|

|

| |

Inside the Mill

When the logs go into the mill the extra long ones are cut into required lengths by a big circular cut-off saw at the head of the log-chain. They are then sent to whichever head-rig their size or character decides. The circular mill takes the smaller and shorter logs. These heavy Long Leaf logs go crashing against that circular and are transformed into lumber at a rate that keeps the visitor staring. The circular is at the left side of the mill, as the logs enter. In the center is the so-called "short" band rig. Lt will cut forty-foot logs, so it isn't so short, after all. This is a double-cutting band mill, the band saws having sawing teeth on both edges, instead of just one edge, and the logs are sliced both coming and going on the carriage. The "long" side is the right hand side of the mill, and here they can saw logs up to 60 feet in length. Here they cut the longest and also the biggest logs that enter the mill. This is also a double-cutting rig, each trip of the carriage as it goes and comes taking a strip from the log.

As the lumber from these three rigs pours out into the mill over the live rolls, there are men and machinery waiting and ready to receive it. Two great edgers stand side by side, and the boards and dimension go through these and have their bark edges cut away. The lumber then is carried on cross-chains through the big piano trimmer, where the ends are made bright, new, and square; then it goes up an incline of chains to the automatic sorter. Here it is sorted for equal lengths, and loaded on kiln cars and made ready for the dry kiln. A lath mill is an adjunct of the sawmill, and one of their novelties is packing the lath into a square pack, rather than a round one. Lath is piled on the top of most of the kiln cars of lumber, and is dried with the lumber.

As it comes from the mill the number three lumber is segregated, and while all the number two and better goes to the dry kilns, the lower grade is sent out to the open air yard for air drying. Thus only low grade lumber is found in the lumber yard at Wiergate.

Timbers Are Dipped

As the timbers are cut they go right through the mill on live rolls. Just after they emerge from the mill they are subjected to a chemical dip to keep them bright, and then continue on their way to the timber dock. Long Leaf timbers are of course one of the specialties of the Wiergate plant. They cut timbers all the way up to 60 feet in length, and of great size when desired. Forty to fifty foot timbers are common products of the mill every day. They are loaded from the timber dock to the cars, and when the timber business is active, car after car of big timbers leaves the mill every day.

When the number two and better lumber, both inch and thicker, emerges from the kilns, it goes into the big cooling shed at the rear of the kilns. When sufficiently cool it is rolled, still on the kiln cars, to the dry storage sheds. There are six of these, mammoth in size and sheds. There are six of these, mammoth in size and standing side by side, with the planing mill off at an angle from them. These sheds hold all the products of the mill in any sort of season, with the exception of the low grades in the open yard. |

|

| |

|

|

| |

Wier's Giant Planer |

|

| |

The planer is built in proportion to the rest of the plant, and is entirely capable of dressing and preparing for market all the lumber the sawmill can produce. It stands between the open yard and the six dry sheds, and the lumber is handled over low plank runways by mules and horses hauling the lumber dollies.

Along the front of the planer and of the dry dressed shed run the lumber loading docks, with sufficient room for an entire train of cars to load at once. |

|

| |

|

|

| |

|

|

| The planing mill where unfinished lumber is moulded into beautiful Long Leaf flooring and dimension. |

|

|

|

|

|

|

| |

Everything around and about the Wiergate plant is neat, clean, and in order. There are no refuse accumulations, no eyesores. The sawmill is itself a particularly open one, and the under part of the mill, instead of being a mass of low-hung timbers, pulleys, and machinery, is open, bright, and clean enough for living quarters. Lt is a grand looking mill, above and below, inside and out.

In the Woods

In the logging department the Wiergate equipment matches that of the milling end. A two-line skidder hauls in the logs to the spur tracks, where a steam loader puts them on the cars and starts them for the mill. Three locomotives perform the woods services. The woods they log look more like a park than a forest. There is practically no underbrush in virgin Long Leaf timber. You can drive almost anywhere through their great forests in an automobile.

A Happy Community

About five hundred men live and move and have their being at the Wiergate plant. It is a particularly happy community. The cares of the outside world cast few shadows over that quiet community. The company maintains a good hotel, a big general store where goods of every sort are sold to their employees at reasonable prices, a modest hospital, a big community house open to all employees and their families, a moving picture theatre, etc.

Enjoys Good Will

E. J. Booth, the manager for Wier at Wiergate, enjoys the confidence and good will of the entire district, as well as their own employees. A university education did not interfere with the making of a fine lumber manufacturer, and a high class citizen who has done much for that section of East Texas, and he has gathered around him a wholesome and useful personnel in every department of the operation, that means much to the success of the plant.

As they were leaving Wiergate after a most pleasant visit, THE GULF COAST LUMBERMAN gang and Tom Wier ran slap bang into a family of farmers, a man and three women, making ribbon-cane syrup in an open kettle syrup mill right alongside of the road. Loaded down with syrup (and Lawdy was it good?) the trio smacked their lips in anticipation of the hot biscuits and syrup that were to come, and bade a grinning good-bye to Wiergate. |

|

| |

|

|

| |

[top] |

|

|

|

|

|

| Text and images were digitized and proofread from the original source documents by Murry Hammond. Contact Murry for all corrections, additions, and contributions of new material. |

| |

|

|